Reinforced Silicon Oxycarbide Composites via Freeze-Casting with Preceramic Polymers

Graduate Student: Claire Kuo

Porous materials are widely used as filters for exhaust control, scaffolds for tissue engineering, electrodes for fuel cell and porous piezoelectric for energy harvesting.

For porous ceramics, pore characteristics (such as pore size, pore shape and tortuosity) are closely related to their functionalities. Freeze casting is one of the techniques where a wide range of pore characteristics are easily tunable. In freeze casting, the pre-ceramic polymer solution is directionally frozen, sublimed, and pyrolyzed, creating an interconnecting ceramic pore structure. The pore characteristics of the freeze-cast structures are affected by processing parameters such as freezing front velocities, solvent anisotropies and thermal gradients, which enables engineers to optimize pore characteristics for respective applications. Despite the functionalities provided by pores, they often serve as crack initiators in materials, which is the main obstacle for a wider utilization of porous materials.

In this project, an established method of strengthening ceramics — adding reinforcement fillers — is integrated into freezing casting to strengthen silicon oxycarbide (SiOC) porous ceramics. Due to the nature of freeze casting process and differences in fillers, the reinforcing effects of fillers on freeze-cast ceramics are more complicated than that of conventional composites. We seek to understand these effects from the standpoint of hydrodynamics, solidification theory, and mechanics of porous materials.

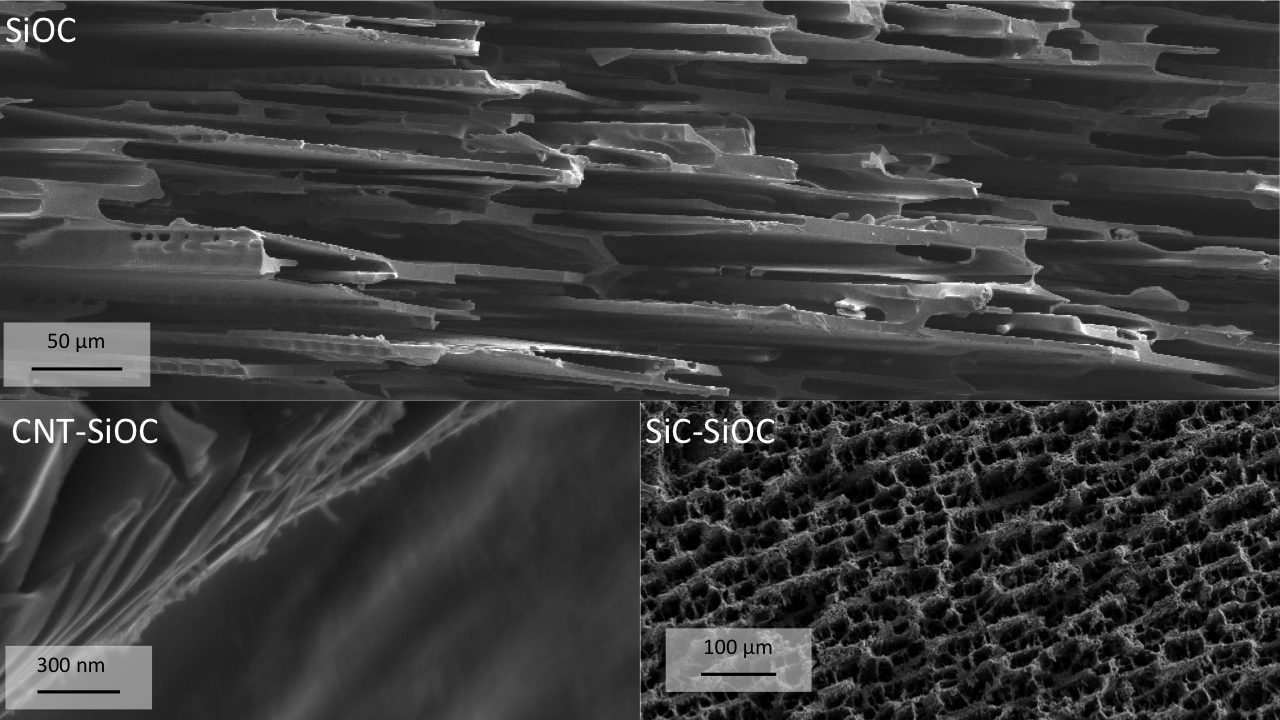

SEM of samples produced via freeze casting.