Fracture Mechanics of Brittle Materials Studied Using Synchrotron X-ray Radiation

Graduate Student: Sara Gorske

Fracture is a critical mode of failure in many materials, especially in brittle ceramics which undergo little plastic deformation. Most studies of fracture in the past have relied on ex-situ methods to assess fracture surfaces after a failure event, and while this mode of analysis has yielded key discoveries on the nature of cracks, research studying cracks in the interior of brittle materials as they are forming and growing has yet to be conducted in depth.

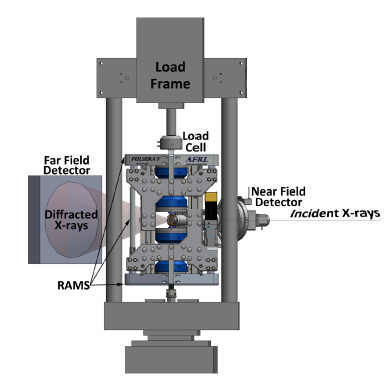

In the Faber group, we are pioneering a new method of fracture study, performed at the Advanced Photon Source (APS) at Argonne National Laboratory (ANL). The work at the APS is a combination of phase contrast micro-computed tomography as a probe to visualize the crack surface, high-energy diffraction microscopy as a method to understand the microstructure and stresses around a crack, and the novel Rotational and Axial Motion System (RAMS), a fixture capable of rotating a specimen 360 degrees for analysis while loading it in compression. By registering cracks to the surrounding microstructure, we stand to learn how inclusions, grain orientation, and anisotropy affect the direction and speed of crack growth. Previously, this technique has only been used to study metal materials; ceramics, with their narrow crack opening and lack of plastic deformation, present new challenges in interpreting and utilizing these results.

The results from the APS are paired with mechanical and chemical investigations done in-house at Caltech to provide guidelines for strain rates and maximum loading, and imaging techniques provide useful information on material microstructure. The presence of inclusions, grains of varying size and orientation, and different levels of anisotropy and toughness will all affect the direction and speed of crack growth. This information is useful not only in designing our experiments but also in our collaboration with phase-field modelers. This computational technique draws from continuum mechanics to describe energy and strain fields around a crack front, and we hope the influx of high-quality data to verify the computations will improve the predictive capacity of this method when applied to new materials.

Fracture Surface of Aluminum Oxynitride Polycrystal

Rotational and Axial Motion System, courtesy of P. Shade and Air Force Research Laboratory