Residual

Stress Analysis of Rare-Earth Silicate Multilayer Environmental Barrier

Coatings

Graduate Student: Fabian Stolzenburg

Due to their high melting temperature, low density, and good

thermomechanical stability silicon-based ceramics (SiC, Si3N4)

are one of the most promising materials systems for high temperature

structural applications in gas turbine engines. However, their

passivating SiO2 surface layer reacts with water vapor

contained in combustion environments. The resulting hydroxide layer

volatilizes, leading to component recession. Environmental barrier

coatings have been developed to shield the substrate from degradation.

Aluminosilicate multilayer coatings have been identified as a promising

system for SiC substrates. Although these materials show good long-term

performance, they are not feasible for temperatures above 1200°C due to

the formation of calcium-containing glass from oxide turbine deposits

and cracking induced by thermal expansion coefficient (CTE) mismatch

between the multilayers.

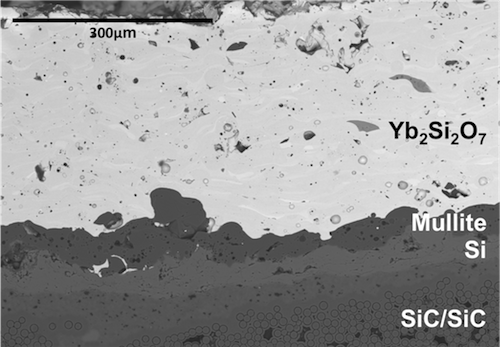

In order to sustain surface temperatures of 1482ºC and substrate temperatures of 1316ºC, as proposed by the Department of Energy, new topcoats are required. The superior chemical compatibility and extremely low volatility of rare-earth silicates such as Yb2SiO5 and Yb2Si2O7, make these materials good candidates for topcoat layers. However, preliminary studies have shown through-thickness cracking in these topcoats and through the intermediate mullite layer. Since cracks such as these allow for the diffusion of water into the underlying coating layers, they will cause premature failure of the coatings.

In this study, the internal strains and stresses, as well as the damage evolution of coatings with ytterbium-silicate topcoats are being investigated. This is primarily done by using high intensity, microfocussed X-rays at the Advanced Photon Source (APS). Using a combination of small-angle and wide angle X-Ray scattering in-situ heating and cooling experiments will allow for the characterization of stresses in the coatings and for the observation of the damage evolution (cracks, pores). In-situ mechanical testing also allows for the determination of elastic constants such as the elastic modulus or Poisson’s Ratio, of these largely unstudied systems. The combination of these methods will allow us to characterize this relatively unexplored material system while improving the effectiveness of these next-generation coatings.

SEM Micrograph of a multilayer enviromental barrier coating.

This work is supported by the Department of Energy, Office of Basic Energy Science, under contract

number DE-AC02-06CH11357